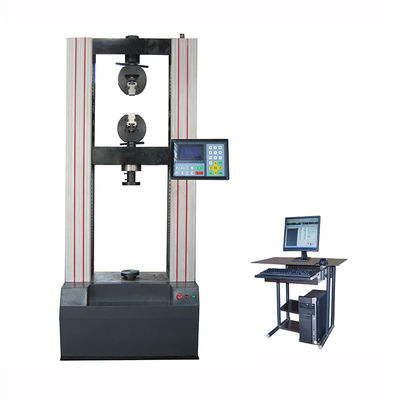

Condition:

New

Style:

Horizontal

Distance Between Tie Bars(Width)(mm):

640mm

Distance Between Tie Bars(Height)(mm):

640mm

Ejector Stroke(mm):

160 Mm

Ejector Force(kN):

80 KN

Theoretical Shot Volume(cm³):

858 Cm³

Injection Rate (g/s):

254 G/s

Machine Type:

Hydraulic

Injection Weight (g):

772 G

Screw Diameter (mm):

58 Mm

Distance Between Tie Bars:

640X640mm

Weight (KG):

10800

Type:

Plastic Injection Machine

Place Of Origin:

Zhejiang, China

Open Stroke(mm):

580 Mm

Model Number:

SHE338G

Brand Name:

SANSHUN

Power (kW):

40 KW

Warranty:

1 Year For Electric Parts 2 Years For Machine Parts

Key Selling Points:

Competitive Price

Applicable Industries:

Manufacturing Plant

Showroom Location:

Egypt, Uzbekistan

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

2 Years

Core Components:

Bearing, Motor, Pump, Gear, PLC, Other, Pressure Vessel, Engine, Gearbox, Screw

Screw Diameter:

58/60mm

Ejector Tonnage:

80 KN

Mould Thickness:

270-650 Mm

Heat Power:

19.1KW

Machine Dimension:

6.7X2.0X1.9M

Machine Weight:

10.8T

Opening Stroke:

580mm

Injection Rate:

254 /272g/s

Injection Weight:

772 /826g

Power:

30KW

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Uzbekistan

Certification:

CE ISO9001 Patent Certificate

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!