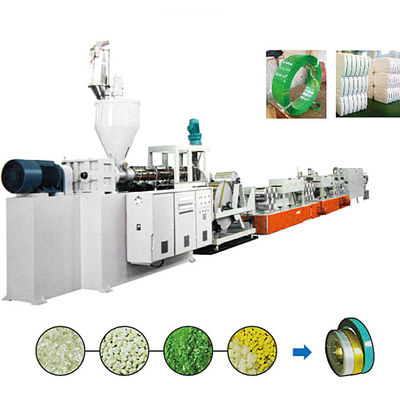

Application:

Strap, Plastic Band/strap

Plastic Processed:

PET

Condition:

New

Screw Design:

Single-screw

Screw Material:

38CrMoALA

Screw Diameter (mm):

120

Screw L/D Ratio:

33:1

Screw Speed (rpm):

100 Rpm

Showroom Location:

None

Place Of Origin:

Anhui, China

Brand Name:

POLYSUN

Voltage:

380/220/440V

Dimension(L*W*H):

L50*W3*H6.5m

Power (kW):

180

Weight:

According To Model

Warranty:

1 Year

Key Selling Points:

High Productivity

Applicable Industries:

Manufacturing Plant

Marketing Type:

New Product 2020

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Bearing, Motor, Gear, PLC, Engine, Gearbox

Raw Material:

Bottle Flakes, 100% Broken Material

Number Of Extruded Strap:

1 To 4

Strap Width:

5-32mm(±0.15mm)

Strap Thickness:

0.5-1.5mm(±0.025mm)

Capacity:

300-400Kg/h

PLC:

Siemens

Color:

Customer Choice

Name:

PET Strap Production Line 1 To 4

Usage:

Making PET Packing Belt

After-sales Service Provided:

Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

None

Certification:

CE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!