Plastic Processed:

PP, PC, ABS, PET, PVC, FRPP/PVC, PPR, EVA, HDPE, MLLDPE, EPS, PA, Polystyrene, PE, LDPE, EVOH, HDPE/PP, ABS/PP, PE/PP, Polylactic Acid

Condition:

New

Style:

Horizontal

Distance Between Tie Bars(Width)(mm):

580 Mm

Distance Between Tie Bars(Height)(mm):

580 Mm

Plasticizing Capacity(g/s):

32

Mold Height(mm):

250 - 590 Mm

Ejector Number:

13

Ejector Stroke(mm):

120 Mm

Ejector Force(kN):

67 KN

Theoretical Shot Volume(cm³):

256 Cm³

Injection Rate (g/s):

221 G/s

Machine Type:

Hydraulic

Injection Weight (g):

505 G

Screw Speed (rpm):

1 - 350 Rpm

Screw Diameter (mm):

45 Mm

Screw L/D Ratio:

24

Distance Between Tie Bars:

580X580mm

Weight (KG):

13000

Type:

Thermoplastics Injection

Place Of Origin:

Guangdong, China

Open Stroke(mm):

525 Mm

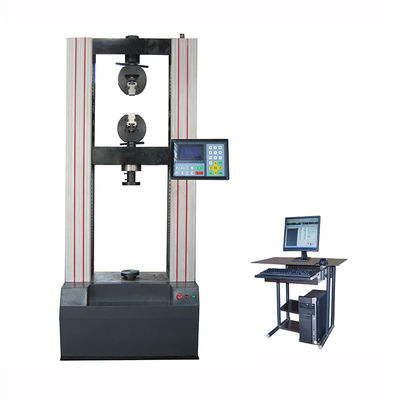

Model Number:

GT3-LS280BT

Brand Name:

LANSON

Power (kW):

52 KW

Warranty:

1 Year

Key Selling Points:

High Rigidity

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Bevera

Showroom Location:

Turkey, United States, Viet Nam, Malaysia

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC, Pressure Vessel, Engine, Gearbox, Screw

Product Name:

LANSON Injection Moulding Machine GT3-LS280BT

Keyword:

High Speed Injection Molding Machines

Function:

Precision, Fast Response, High Efficiency And Energy Saving

Application:

Thin Wall Package Products Making

Prices:

Negotiable

Plastic Type:

Thermoplastic

Clamping Force (kN):

2800

Automatic:

Yes

After-sales Service Provided:

Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Turkey, United States, Viet Nam, Malaysia

Certification:

CE ISO9001